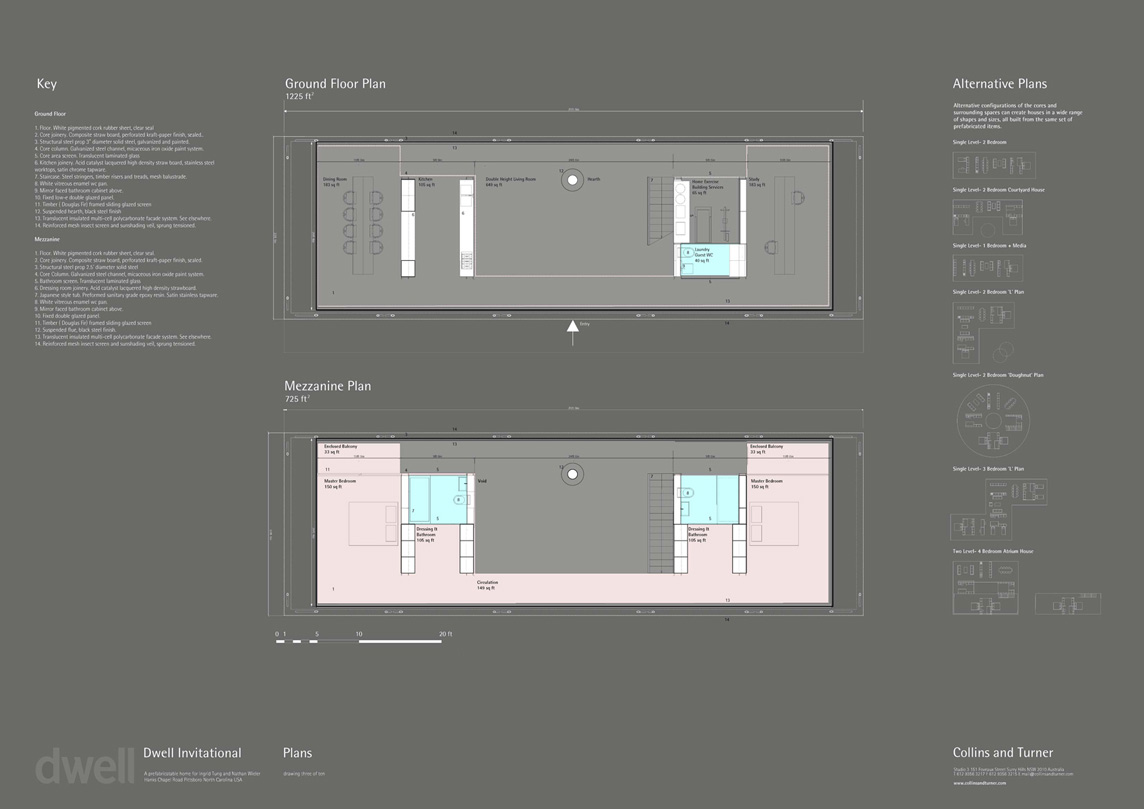

In 2003, Collins and Turner were invited by San Francisco based Dwell magazine to prepare a proposal for the ‘Dwell Home’. A prototype for a new generation of mass produceable modular homes, the site for the first house is in Chapel Hill, North Carolina.

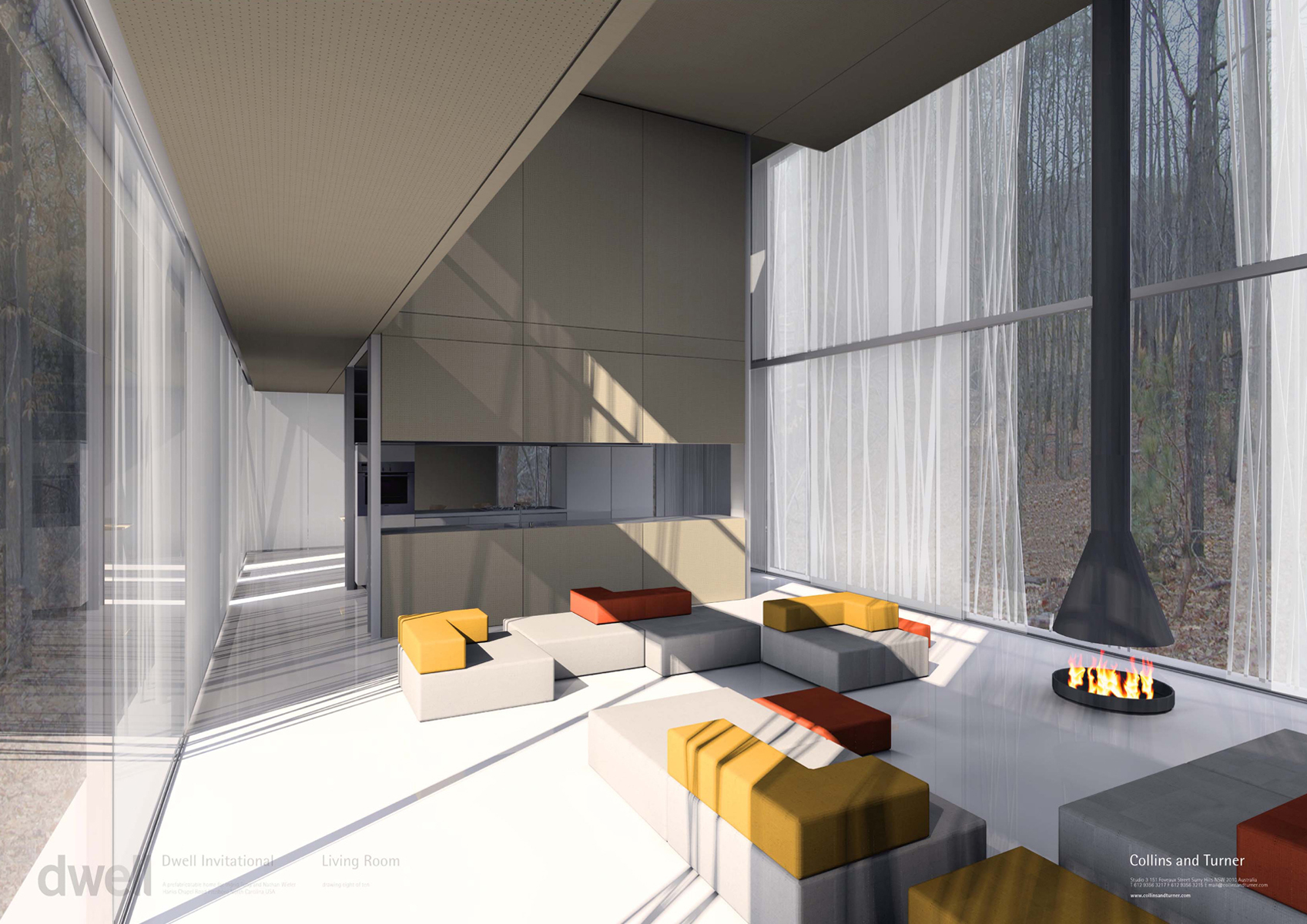

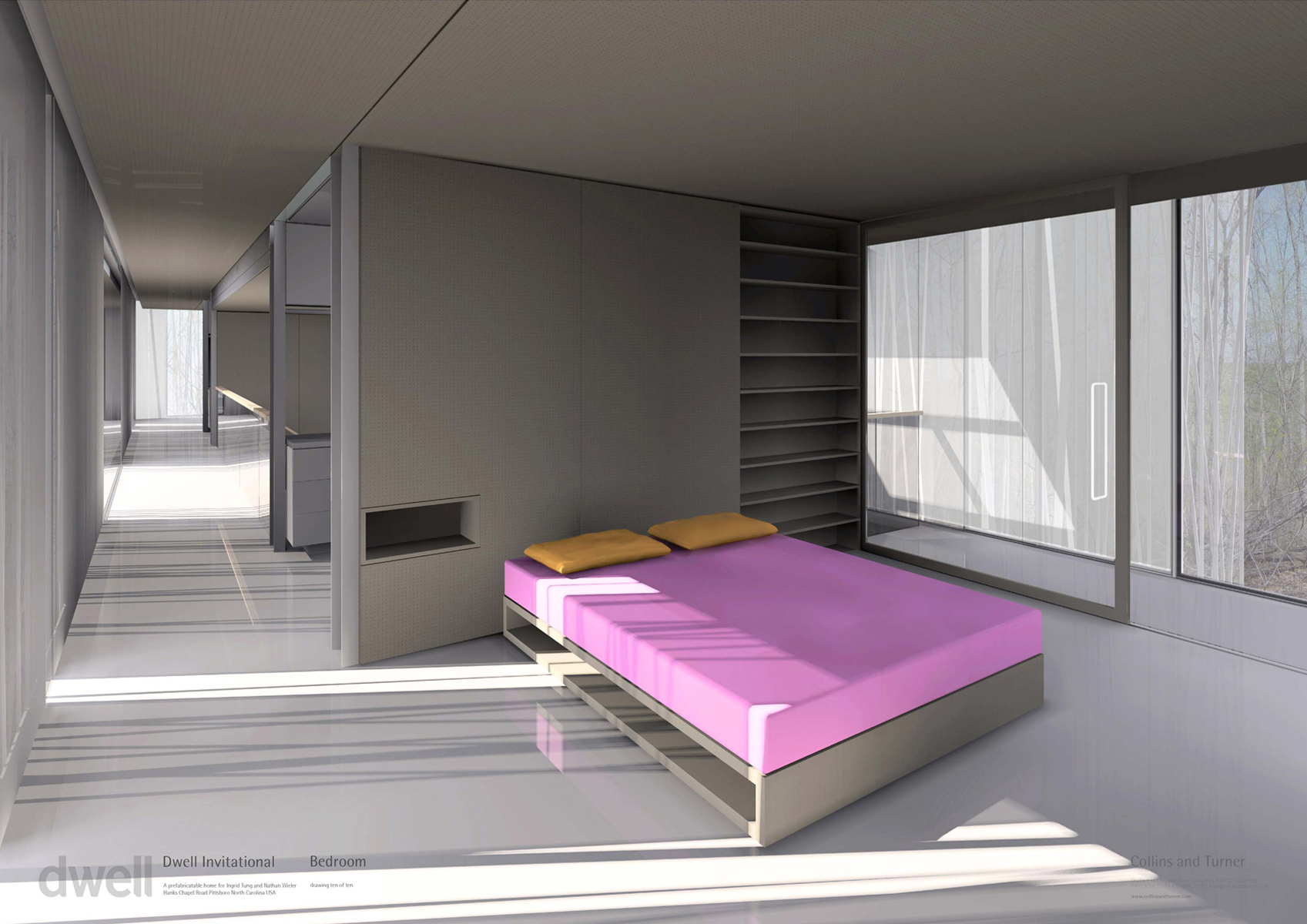

The house is conceived of as a series of spaces wrapped in a light-giving, thermally active envelope, shrouded by a multi-functional mesh veil which incorporates the lines of the surrounding landscape in abstract. Internally, a rhythm of linear core elements replaces walls to shape a variety of living spaces.

The structure is a simple prefabricated steel frame supporting precast concrete floor panels at ground level, and compressed straw panels for the first floor and roof. The main load-bearing structure forms “book-ends” to the core elements that contain service functions.

The cladding is a translucent / transparent ventilated cavity system, enveloped by a fly screen-like mesh veil performing as sun shading, insect screening and structural bracing. The mesh is reinforced with carbon fibre rods, like battens reinforcing yacht sails, providing lateral stability to the structure. The density of the weave of the mesh varies, responding to sun-shading and privacy requirements. The inner skin of the façade is made of multi-cell polycarbonate. Utilising the Stack Effect it tempers the internal environment, minimising energy consumption for heating and cooling. The translucency also reduces energy consumption by providing ample daylighting. With large opening window areas, rooms can become loggia–like. The exterior walls are a contemporary interpretation of traditional “jalousie balconies” commonly used in the region to create a verandah protected from the prevalent flying insects. The veil allows new ways of living intimately with the outdoors.

- Structure

- Enstruct

- Consultant

- ESD Steensen Varming